Off Namulondo Road, Bweyogerere Kampala Uganda

info(at)steelworksuganda.com

Pilot: +256 759 744 111

Mobile: +256 392 261 381

Mobile: +256 393 265 760

Hot rolled structures, also known as Conventional Steel Structures, are the most common type of steel structures used in Africa today. In conventional steel structures, mill-produced hot rolled sections (beams and columns) are used as the primary members, rather than tapered built-up beams (PEB). However, our hot rolled structures are still pre-engineered and pre-fabricated for onsite bolting only.

Steel buildings are designed considering every function of the building beginning from the project phase. The safety and the quality standard of the building are considered at the design process of the structure. Accurate and detailed project planning is done to provide the most safe and economic structure to the user on time.

Structural steel is fabricated off-site under controlled conditions, ensuring a high-quality product and reducing the number of costly fixes at the job site. This also allows for just-in-time delivery, accelerating overall project schedules.

Structural steel is reliable and predictable. It’s produced to precise tolerances in size and strength. This makes steel easier to design and use. Furthermore, since it’s at full strength as soon as it’s erected, project schedules are predictably shorter.

Structural steel leads the construction industry with a fully integrated supply chain using advanced technology at all stages of design and construction. This technology has been proven to reduce or eliminate errors, improve safety and lower project costs.

Structural steel provides owners with buildings that generate revenue earlier, maximize the amount and use of floor space, are easy to modify and easier to sell. They are also aesthetically pleasing.

Structural steel is the most economical building framing material. Project costs are lowered as a result of reduced labour and equipment requirements, lower foundation costs and lower ongoing building maintenance expenses.

Delivery times can be faster as hot rolled beams and columns are already produced in standard sections, and hence there is a reduction in the fabrication processes (less offsite welding)

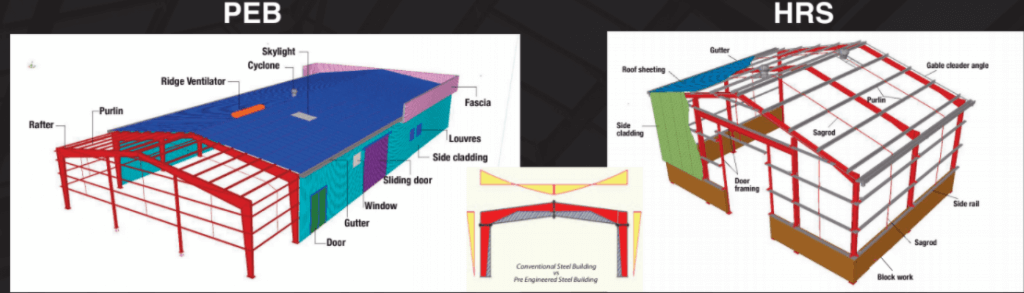

Since Hot Rolled Structures are built with mill-produced beams and columns in specific standard sizes, they are generally heavier and therefore much more rigid than PEB

Since HRS are the standard conventional type of structures predominantly used in the region, most Consultants are more familiar with the design and use of the same.

Delivery times can be faster as hot rolled beams and columns are already produced in standard sections, and hence there is a reduction in the fabrication processes (less offsite welding)

Since Hot Rolled Structures are built with mill-produced beams and columns in specific standard sizes, they are generally heavier and therefore much more rigid than PEB

Since HRS are the standard conventional type of structures predominantly used in the region, most Consultants are more familiar with the design and use of the same

There are two main types of heavy gauge steel buildings: Hot Rolled Structures (HRS) and Pre-Engineered Buildings (PEB)

“The SSL advantage is that we can offer a hybrid solution combining the advantages of PEB together with HRS for certain elements, to provide a combined unsurpassed economic & technical solution.”